Urban construction presents a distinct constellation of challenges that differentiate it from greenfield development. Sites are often spatially constrained, bounded by existing infrastructure, and subject to stringent regulations regarding noise, traffic, and public disruption. The conventional methodology of concrete delivery—reliant on large transit mixers and separate pumping apparatus—frequently exacerbates these challenges, creating logistical gridlock and inefficiency. In this context, the concrete pump mixer emerges as a purpose-engineered solution, integrating batching and placement functions into a single mobile unit. This machine is not merely an alternative piece of equipment; it is a strategic instrument designed to reconcile the demands of modern construction with the inherent limitations of the urban environment, transforming potential obstacles into manageable processes.

Spatial Optimization: Navigating Confinement and Congestion

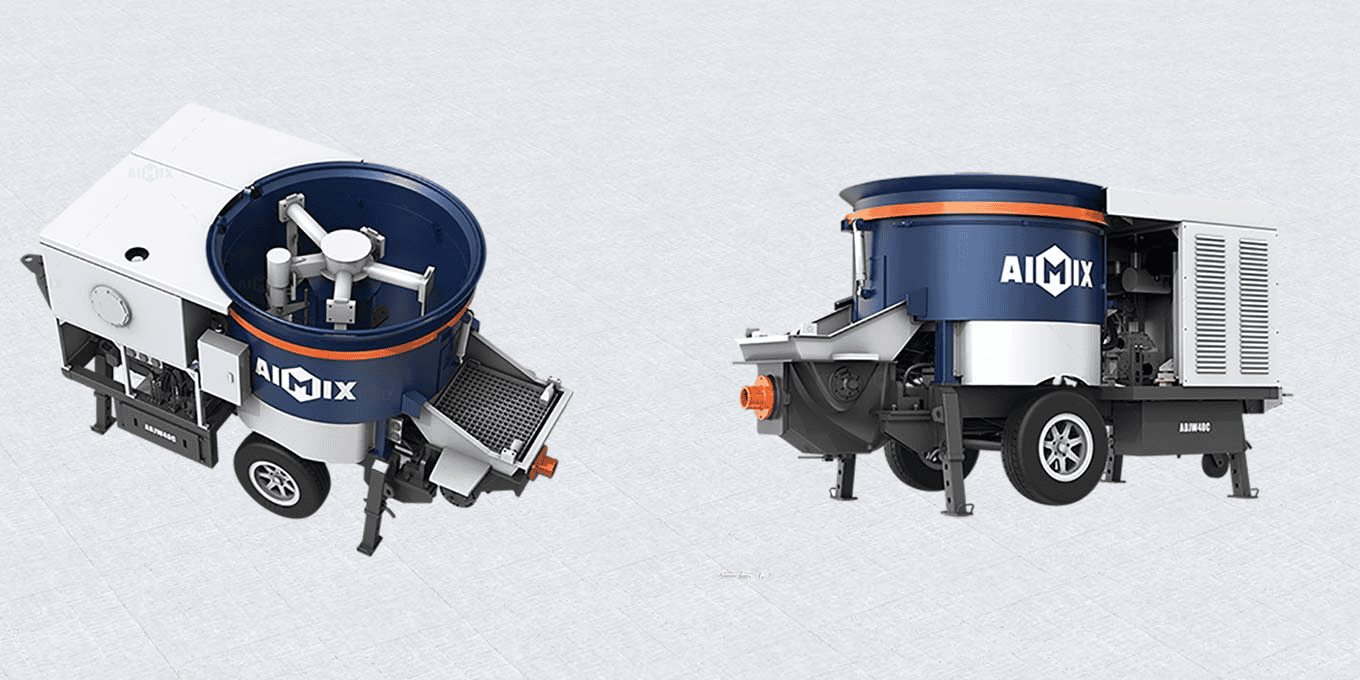

The foremost advantage of a concrete pump mixer in an urban setting is its exceptional spatial economy. Traditional concrete placement requires a staging area for pump setup, a continuous stream of transit mixer trucks for supply, and sufficient maneuvering room for both. In densely built city centers, alleyway projects, or tight infill lots, this spatial footprint is often unavailable. The concrete pump mixer consolidates these functions. It requires only a single vehicle footprint for both production and placement. The machine can be positioned in a single parking space, on a closed lane of traffic, or on a minimally prepared section of the site itself. From this static position, its articulating or telescopic boom can often reach pour locations over obstacles, eliminating the need for internal site access by heavy vehicles.

This consolidation yields immediate benefits in reduced labor intensity and enhanced placement precision. The integrated system negates the need for multiple workers to manage hose lines from a distant pump or to guide concrete chutes from truck to formwork. Operators can control the pour directly from the boom’s remote control, placing material with pinpoint accuracy into complex forms, densely reinforced sections, or elevated slabs. This precision minimizes waste, improves finished surface quality, and significantly enhances worksite safety by reducing the movement of workers around pouring concrete and maneuvering delivery vehicles.

Logistical and Temporal Efficiency: Streamlining the Urban Supply Chain

Urban construction schedules are notoriously sensitive to delay, with costs escalating rapidly due to downtime. The concrete pump with mixer for sale introduces a paradigm of logistical sovereignty. It operates on a just-in-time production model. Raw materials—aggregates, cement, and water—are carried onboard or supplied from small, discreet stockpiles. Concrete is batched and mixed immediately prior to pumping, collapsing the supply chain from hours of transit time to minutes of production time. This autonomy liberates the project from the vulnerabilities of external ready-mix supplier schedules, city traffic conditions, and the limited delivery windows often imposed in urban cores.

Furthermore, this integrated workflow accelerates project timelines. The continuous, on-demand production capability allows for pours to proceed at an optimal pace without interruption. There are no gaps waiting for the next truck to arrive, no risks of concrete setting in the drum due to traffic delays, and no need to coordinate the intricate dance between pump and fleet. The workflow becomes linear and controlled. This temporal efficiency is not merely a convenience; it is a critical factor in meeting tight construction schedules, minimizing rental costs for ancillary equipment, and reducing the overall duration of neighborhood disruption—a key consideration for community relations and regulatory compliance.

Versatility and Specialization: Addressing the Urban Fabric's Diverse Demands

The urban environment demands a high degree of versatility from construction equipment. Projects range from heritage building renovations and boutique commercial fit-outs to the construction of high-rise residential towers and complex public infrastructure. The concrete pump mixer is uniquely adaptable to this spectrum. Its ability to produce concrete on-site in controlled, small batches makes it ideal for the precise, sequential pours required in renovation and retrofit projects, where access is limited and volumes are modest. For new construction, its pumping capability allows it to service high-rise projects up to a certain vertical reach, often serving as the primary pump for lower-to-mid-rise structures or as a supplementary unit for specific elements.

Critically, this on-site batching control enables the use of specialized concrete mixes that are essential for modern urban construction. Engineers can specify high-performance mixes for increased strength or durability, self-consolidating concrete for densely reinforced members, or sustainable mixes incorporating supplementary cementitious materials like fly ash or slag. The pump mixer can accurately produce these bespoke formulations in the required quantities, ensuring material performance without the waste and logistical complexity of ordering small loads from a central batch plant. In essence, the mini concrete pump for sale provides the dual capability of logistical simplification and technical sophistication, making it an indispensable tool for overcoming the multifaceted challenges of building within the existing urban fabric. It represents a convergence of mobility, precision, and adaptability tailored for the cityscape.