In the vast and often overlooked landscapes of rural communities, the act of building is more than just construction; it is a fundamental expression of progress and hope. Yet, for local builders and aspiring homeowners, this journey is frequently fraught with formidable obstacles that can stifle development before it even begins. The dream of a new home, a community school, or a small business premises is often tempered by the harsh realities of logistical nightmares, prohibitive costs, and a scarcity of resources. Traditional methods, while familiar, are labor-intensive and time-consuming, limiting the scale and pace of development. However, a quiet revolution is underway, powered not by complex, unattainable technology, but by pragmatic and accessible machinery. The advent of simple, cost-effective concrete batching plants and versatile mixer pumps is fundamentally altering this narrative, turning remote building sites from places of immense challenge into hubs of tangible opportunity and self-reliant growth.

The Rural Construction Conundrum: Overcoming Logistical and Economic Hurdles

The challenges facing rural builders are a complex web of interrelated issues. Distance is the first and most pervasive adversary. Transporting ready-mix concrete from urban plants over long, unpaved roads is not only exorbitantly expensive but also highly unreliable. The viability of the concrete itself is jeopardized by long transit times, often resulting in setting before arrival and catastrophic material loss. This logistical quagmire imposes a severe constraint on what projects can even be contemplated, effectively placing a premium on development that prices out many community members. Compounding this is a frequent scarcity of highly skilled labor. While there is no shortage of willingness to work, the specialized techniques required for large-scale, efficient concrete work are not always readily available. This reliance on manual mixing and placement is profoundly limiting, capping the ambition of projects and consuming inordinate amounts of time and physical effort. Traditional methods, though steeped in local knowledge, lack the efficiency and consistency required for modern structures, creating a developmental ceiling that is difficult to break through.

A Practical Arsenal: The Transformative Power of Accessible Technology

The introduction of appropriately scaled technology provides a powerful and practical solution to these entrenched problems. Small, modular concrete batching plants represent a paradigm shift in how materials are sourced. These plants can be established locally, allowing builders to produce high-quality concrete on demand, using locally available aggregates, sand, and cement. This single innovation severs the costly tether to urban suppliers. The economic liberation is immediate and significant; funds once allocated to transportation can be redirected into the project itself, allowing for better materials or a larger scope of work. The consistency of machine-mixed concrete also ensures a higher standard of quality and structural integrity than is typically possible with variable manual methods, leading to buildings that are safer and more durable.

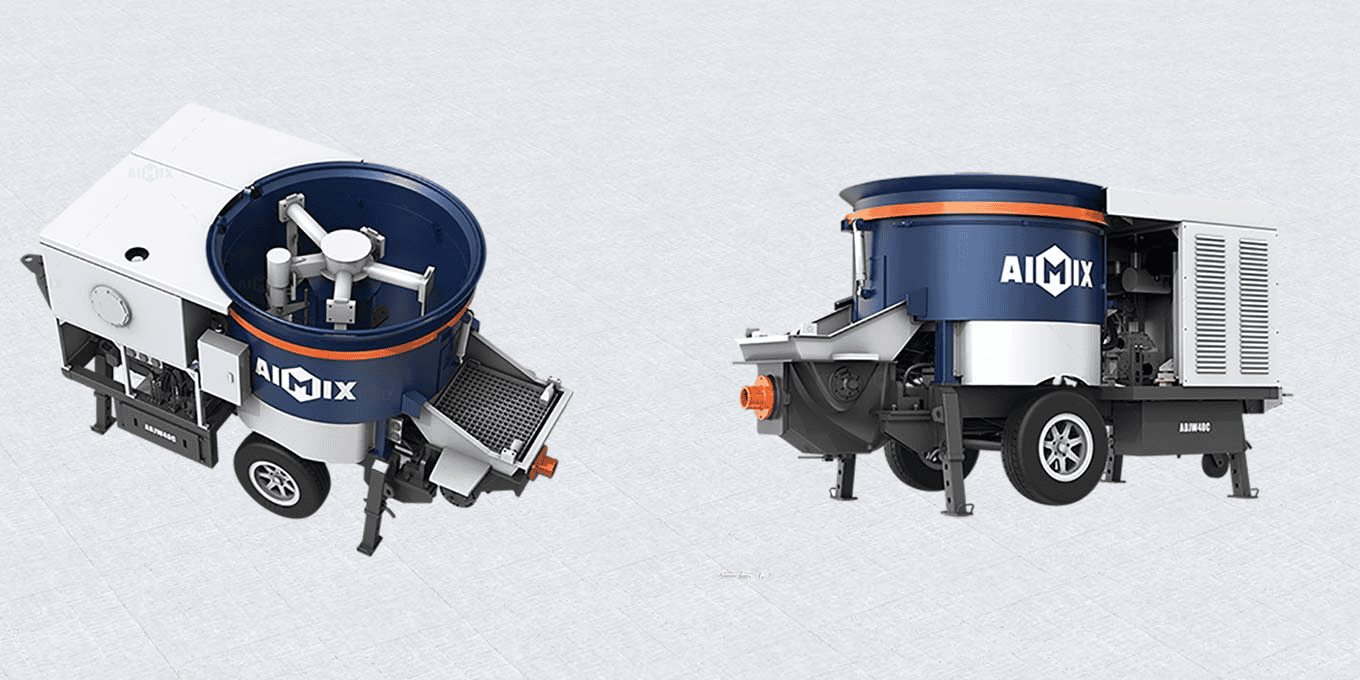

Complementing the batching plant is the concrete mixer with pump, a machine of remarkable versatility. This single unit combines the functions of mixing and pumping, eliminating the need for multiple pieces of equipment and a large crew. Its most profound advantage in a rural context is its ability to place concrete in locations that are otherwise difficult or impossible to access. Whether it's the foundation for a house on a steep incline, the roof of a single-story building, or a site obstructed by existing structures, the pump's articulated boom or flexible pipeline delivers the material with precision. This capability drastically reduces the physical labor involved in moving heavy wheelbarrows and minimizes material waste from spillage. The synergy created by using a small batching plant alongside a mixer pump creates a self-contained, highly efficient production and placement system. This streamlined workflow accelerates project timelines from months to weeks, enabling small teams of local workers to undertake and complete projects that were previously considered the domain of large, external contractors.

Cultivating Prosperity: The Ripple Effects of Localized Construction

The impact of this technological empowerment extends far beyond the completion of a single building. It sets in motion a powerful ripple effect that revitalizes the entire local economy and social fabric. For the local builder, this equipment is not just a tool but a catalyst for entrepreneurship. An individual or a small cooperative that invests in a concrete plant and concrete mixer with pump for sale transforms from a laborer into a service provider. They can now offer a complete concrete solution for their community, undertaking contracts for homes, shops, agricultural storage, and small-scale infrastructure. This creates a new, viable business model that generates sustainable income and fosters a sense of professional pride and ownership. The reliance on outside contractors diminishes, ensuring that money circulates within the community, strengthening the local economic ecosystem from within.

This newfound capacity for construction directly accelerates community development. Essential projects that were once perpetually on a waiting list due to cost and complexity can now be initiated locally. The construction of a reliable water reservoir, a small health clinic, or reinforced grain storage facilities becomes a feasible undertaking. Improved roadways and small bridges can be built to better connect the community to markets. This self-directed development fosters a powerful sense of agency and collective accomplishment. Communities are no longer passive recipients of aid but active architects of their own future. They can prioritize their most pressing needs and address them with a speed and efficiency that was previously unimaginable. This builds a tangible foundation for sustainable growth, where each completed project adds to the community's assets and capabilities, making the next one easier to achieve. The simple act of producing and placing concrete becomes a cornerstone for lasting prosperity, proving that true empowerment often comes not from grand gestures, but from providing the right tools to capable hands.