The gravel crusher market is undergoing a profound and necessary transformation, one that is being gently but firmly guided by a global shift toward environmental stewardship. For business owners and operators, these changes can feel daunting, but it's important to recognize them not as constraints, but as a pathway to more resilient, efficient, and community-minded operations. Stricter environmental policies are no longer peripheral considerations; they have become central drivers of innovation, compelling manufacturers and contractors alike to reimagine how crushing is performed. This evolution touches every aspect of the industry, from the fundamental engineering of the machines to their deployment on-site and the very definition of a profitable project. Understanding these trends is the first step toward adapting successfully and building a business that is prepared for the future.

The Regulatory Catalyst: How Policies are Reshaping Equipment Design

At the most fundamental level, environmental regulations are directly influencing the core design and functionality of new gravel crushers. The most visible change is in the widespread adoption of comprehensive dust suppression systems. Modern units are now equipped with sophisticated misting cannons, integrated water spray bars at transfer points, and sometimes even fabric filter baghouses that capture particulate matter with remarkable efficiency. This isn't just about adding a few spray nozzles; it's a holistic approach to containing dust from the moment material enters the feeder to its final deposition on a stockpile. Noise abatement is another critical frontier. New machines feature sound-dampening enclosures for engines and hydraulic power packs, specially designed crusher cavities that reduce acoustic impact, and vibratory screens engineered for quieter operation. Furthermore, engine manufacturers are continuously innovating to meet stringent emission standards like Tier 4 Final and EU Stage V, which drastically reduce harmful nitrogen oxides and particulate matter. These design imperatives ensure that new equipment can operate in closer proximity to communities and in environmentally sensitive areas, opening up new project opportunities while protecting the well-being of workers and the public.

The Operational Shift: Embracing the Circular Economy On-Site

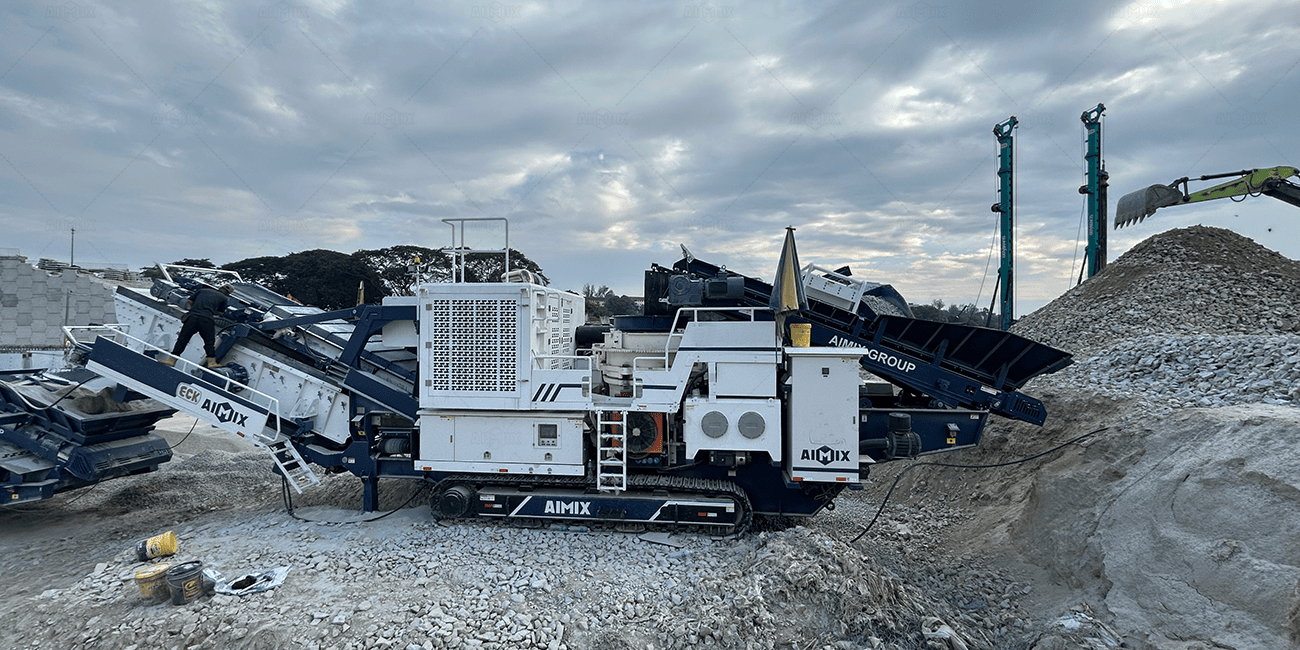

Beyond machine specifications, environmental policies are fostering a complete operational shift toward a circular economy. The high cost and diminishing availability of landfill space, coupled with regulations that discourage the disposal of construction and demolition (C&D) waste, have made on-site recycling a standard practice rather than a niche service. This has elevated the mobile crusher from a simple aggregate producer to a central tool for material management. Crushers are now routinely deployed to process demolition concrete, reclaimed asphalt pavement, and other inert waste materials directly on the project site. This process, known as in-situ recycling, eliminates the environmental and financial cost of transporting waste to a distant landfill and simultaneously creates a valuable resource. The resulting recycled aggregate can be used for road base, backfill, or even in new concrete mixes, closing the material loop beautifully. This approach not only demonstrates environmental responsibility but also provides significant cost savings on material procurement and waste disposal, making projects more sustainable in both an ecological and economic sense.

The Market Transformation: New Business Models and Strategic Advantages

These cumulative changes are catalyzing a broader market transformation, creating new business models and rewarding companies that proactively adopt green practices. Contractors who have invested in modern, compliant stone crusher plant equipment are finding a competitive edge. They are often preferred for public works projects and private contracts where environmental compliance and sustainability credentials are key selection criteria. This has given rise to specialized service providers focused solely on mobile crushing and recycling, offering their services to demolition contractors and construction firms that do not own their own equipment. The business case has expanded from simply selling crushed stone to offering a comprehensive "waste-to-resource" service. This model not only generates revenue from the processing fee but also from the sale of the high-quality recycled aggregate produced. Companies that can transparently track and report the environmental benefits of their operations—such as tons of material diverted from landfill and reductions in carbon emissions from avoided transport—are building powerful brand reputations. In this new landscape, environmental policy is not a barrier to business; it is the architect of a more sophisticated, profitable, and sustainable industry for everyone involved.