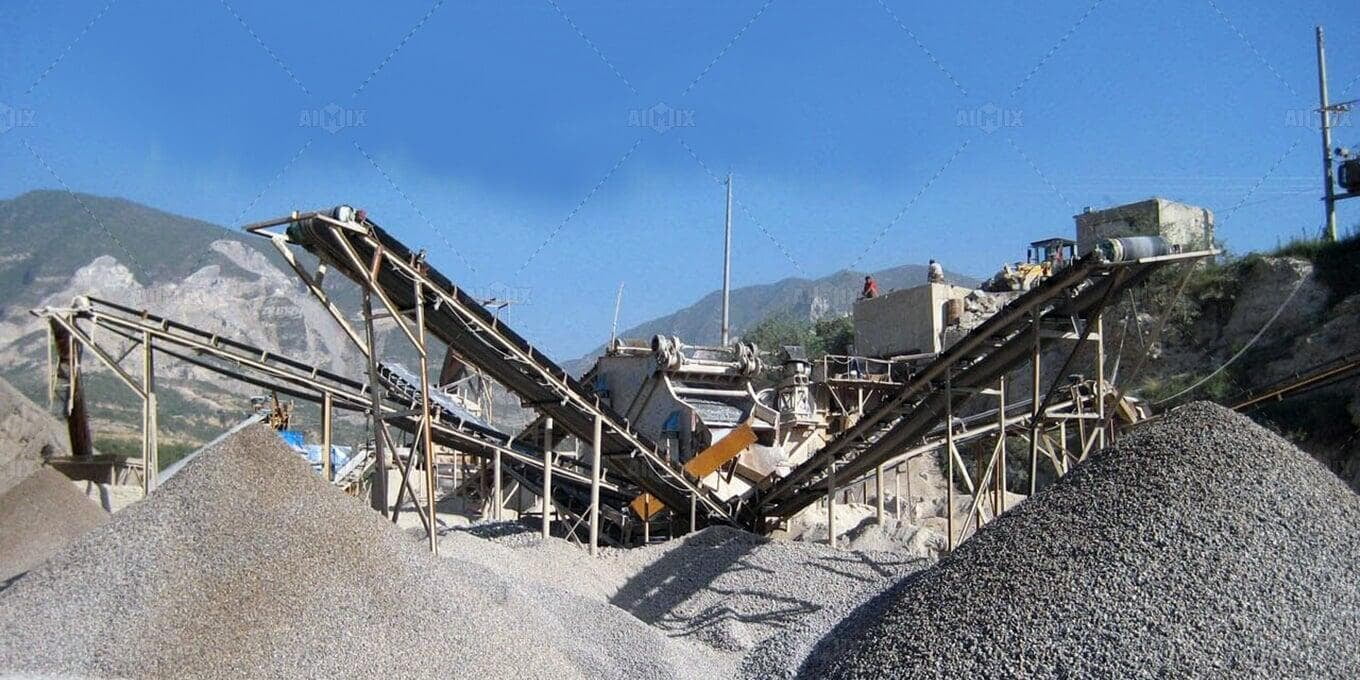

The economics of crushing is a fascinating subject, particularly when delving into the specifics of 150 TPH (tons per hour) stone crushers. This analysis not only sheds light on the financial implications of purchasing such machinery but also explores their operational efficiencies, maintenance costs, and market dynamics. Understanding the 150 tph stone crusher price structure for these machines is essential for businesses looking to optimize their investment and ensure profitability.

The Cost Components of 150 TPH Stone Crushers

When assessing the price of a 150 TPH stone crusher, it's crucial to dissect the myriad components that contribute to the overall cost. Initial purchase price stands as the most apparent factor, often influenced by the brand and model of the crusher. However, other costs such as transportation, installation, and commissioning can add significantly to the total expenditure.

Beyond the initial costs, one must consider operational expenses. This includes power consumption, which can be substantial given the heavy machinery's energy demands. Additionally, wear and tear on components creates ongoing maintenance costs that can accumulate over time. These costs must be meticulously calculated to provide a comprehensive understanding of the total investment required for a stone crushing operation.

Moreover, the market fluctuations in raw materials and machinery can also impact pricing. Factors such as supply chain constraints, geopolitical tensions, and economic trends can lead to volatile price changes. Understanding these fluctuations is essential for prospective buyers to time their purchases strategically.

Operational Efficiency and Cost-Effectiveness

The efficiency of a 150 TPH stone crusher is a pivotal aspect that directly correlates with its economic viability. Operational efficiency can be assessed through various metrics, including throughput, fuel consumption, and maintenance cycles. A machine that maximizes output while minimizing input costs is invariably more desirable.

Investing in advanced technologies such as automation and monitoring systems enhances a crusher's operational efficiency. These systems can provide real-time data on performance metrics, enabling operators to make informed decisions that lead to reduced downtime and improved productivity. Such enhancements not only optimize the crushing process but also contribute to a more sustainable operation.

In addition, the selection of the right type of crusher—be it a jaw, cone, or impact crusher—can play a significant role in achieving desired outcomes. Each type has its inherent strengths and weaknesses, making it imperative for businesses to align their operational needs with the crushing and screening plant they choose. The right match can yield a more efficient crushing process, ultimately leading to greater cost-effectiveness.

Market Dynamics and Price Variability

The pricing landscape for 150 TPH stone crushers is influenced by a confluence of market dynamics. Demand and supply play a critical role; a surge in construction and mining activities can lead to increased demand for crushing equipment, thereby driving prices upward. Conversely, economic downturns can result in a glut of machinery, forcing prices to dip.

In addition to demand fluctuations, regional variations in pricing can also occur. Factors such as transportation costs, local market conditions, and the availability of skilled labor can create disparities in crusher prices across different geographical locations. Hence, potential buyers should conduct thorough market research to identify the most favorable conditions for their purchase.

Another critical element is the competition among manufacturers. Established brands often command higher prices due to their reputation for quality and reliability. However, emerging manufacturers may offer more competitive pricing to gain market share, presenting buyers with a range of options. Evaluating the value proposition provided by different brands, considering aspects like warranty, service support, and spare parts availability, can lead to more informed purchasing decisions.

In conclusion, navigating the economics of crushing—particularly with respect to 150 TPH stone crushers—requires a multifaceted approach. By understanding the cost components, maximizing operational efficiency, and analyzing market dynamics, businesses can make astute investments that enhance their profitability and operational success. Amidst the myriad of choices available, informed decision-making stands as the keystone to thriving in a competitive landscape.