Road construction depends on a foundation of durable, well-processed materials, and gravel remains one of the most indispensable components in infrastructure development. Whether forming the base layer of highways, stabilizing rural roads, or enhancing urban pavements, crushed gravel plays a pivotal role in ensuring longevity and performance. The quality of gravel, largely determined by the crushing process, directly influences the road’s ability to withstand heavy loads, harsh weather, and constant wear. With infrastructure demands rising globally, understanding the role of gravel crusher for sale in road construction becomes essential for both cost-effective and sustainable development.

The Crucial Role of Gravel in Road Construction

A well-constructed road begins with a strong foundation, and gravel serves as the backbone of this structure. One of its primary functions is to provide load-bearing capacity, distributing the weight of vehicles and preventing surface deformation over time. Poorly compacted or inadequately crushed gravel can lead to road failures, causing cracks, potholes, and hazardous driving conditions.

Beyond strength, drainage and erosion control are critical considerations in road design. Gravel prevents water accumulation by allowing efficient percolation, reducing the risk of surface damage caused by freezing, thawing, and waterlogging. Without a properly graded gravel base, excessive moisture can undermine the road’s stability, leading to premature degradation.

Cost efficiency also plays a decisive role in gravel’s dominance over alternative materials. Compared to concrete or asphalt, crushed gravel is significantly more economical while still delivering commendable durability. Its availability in various regions and ease of processing make it a practical choice for both large-scale infrastructure projects and local road developments.

Types of Gravel Crushers and Their Impact on Material Quality

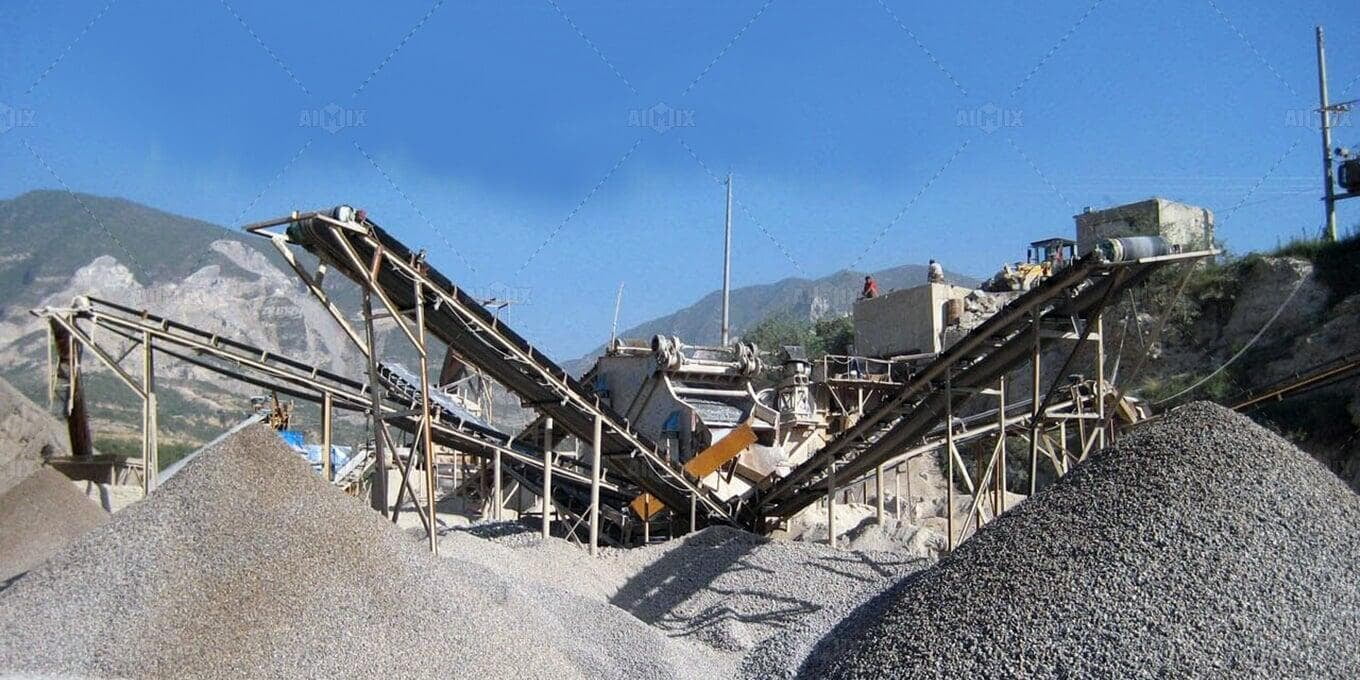

The quality of crushed gravel hinges on the equipment used to process it. Jaw crusher for sale, cone crusher, and impact crusher are the most commonly employed machines, each offering distinct advantages based on the project’s needs.

- Jaw crushers are ideal for initial crushing, breaking down large rocks into manageable sizes. They provide robust performance but may lack the ability to produce finely graded gravel needed for smooth road surfaces.

- Cone crushers refine gravel further, shaping particles into uniform sizes that enhance road stability. Their precision makes them essential for applications requiring consistent grading.

- Impact crushers are particularly effective in producing high-quality gravel with angular shapes, essential for superior interlocking and compaction in road construction.

Crushed gravel’s particle size distribution directly influences road durability. Well-graded material with a mix of fine and coarse particles compacts more effectively, creating a stable base resistant to displacement and erosion. Advanced crushing technology has further optimized this process, reducing material waste and improving overall efficiency. Modern crushers integrate automation and real-time monitoring, ensuring uniform output that meets stringent infrastructure standards.

Challenges and Future Trends in Gravel Processing for Infrastructure

Despite its advantages, gravel processing presents environmental and logistical challenges that must be addressed. The extraction of natural gravel depletes resources and disrupts ecosystems, making sustainable sourcing an urgent priority. Stricter regulations on quarrying operations push industries to seek alternative solutions, such as manufactured aggregates and recycled construction materials. Get the aggregate applications after crushing here: https://aimixgroup.com/stone-crusher-plants/aggregate/

To combat waste, manufacturers are developing innovative crushing technologies that enhance efficiency and minimize dust emissions. New designs incorporate energy-saving mechanisms, reducing fuel consumption and operational costs. Additionally, mobile crushers are gaining traction, enabling on-site processing and cutting transportation-related carbon footprints.

The rise of recycled aggregates is also reshaping the industry. By repurposing demolition debris into high-quality gravel, construction firms can significantly reduce environmental impact while cutting material costs. Governments and urban planners increasingly advocate for recycled materials in road projects, reinforcing the shift towards a more circular economy in infrastructure development.

As demand for durable and cost-effective roads escalates, the role of gravel crushers in road construction will remain indispensable. Adapting to new technologies and sustainable practices will not only enhance efficiency but also ensure that future infrastructure is built with resilience and responsibility.