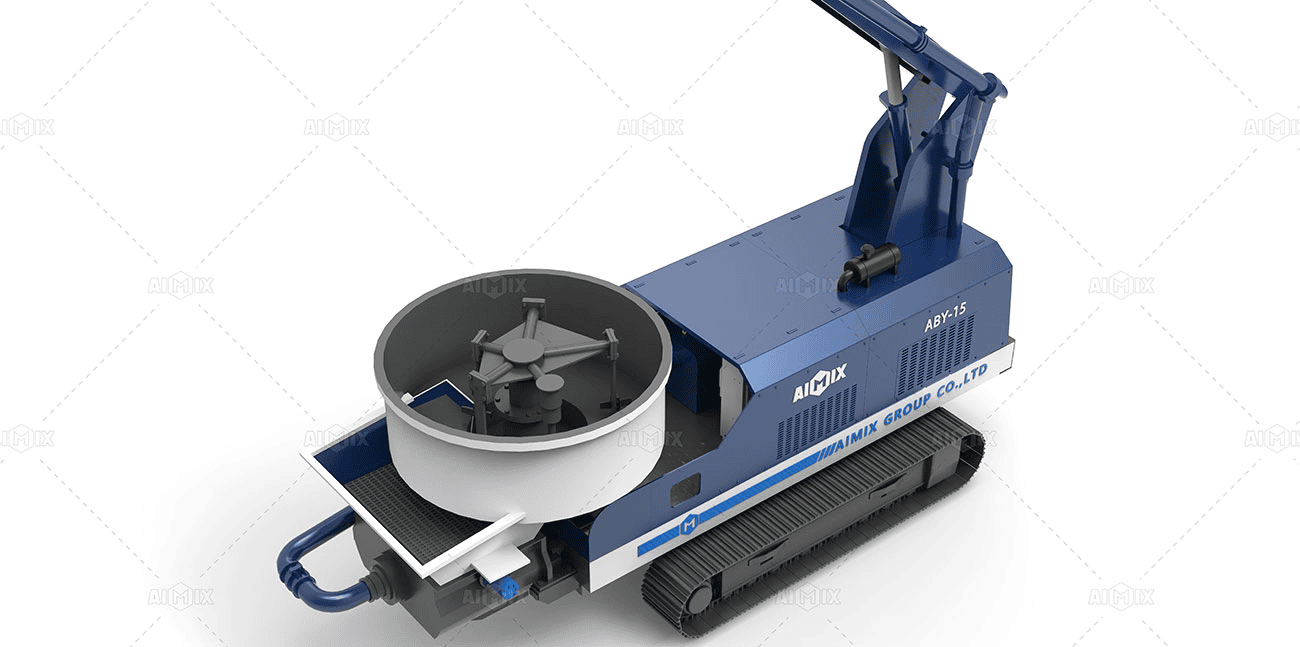

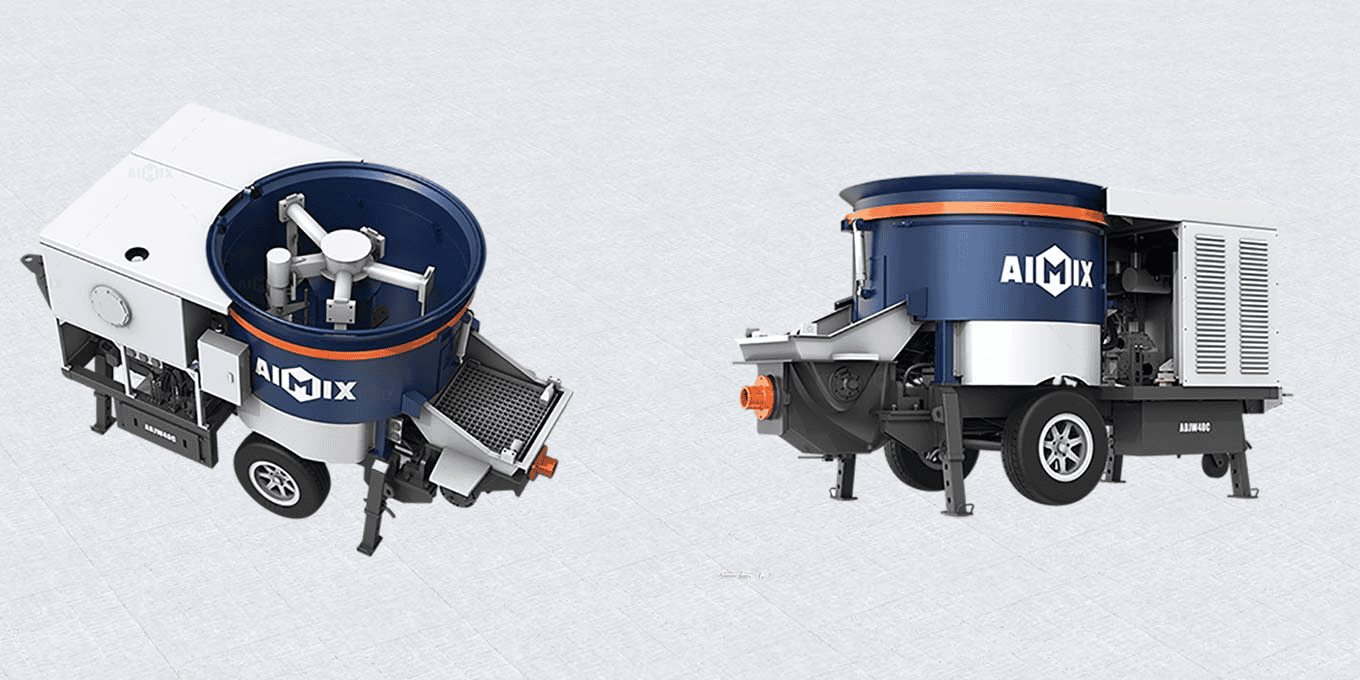

Many contractors settle for "adequate" concrete mixing, unaware that their equipment's underperformance silently erodes both project quality and profitability. The stubborn persistence of traditional mixing systems in an era of advanced technology represents nothing less than willful negligence toward both operational excellence and structural integrity. While conventional concrete mix pump may produce concrete that meets minimum specifications, they consistently fail to unlock the full potential of modern material science. The transition to planetary mixer-equipped systems isn't merely an upgrade—it's an essential evolution for any serious concrete professional.

The concrete industry's resistance to technological advancement borders on professional malpractice when considering the demonstrable superiority of planetary mixing technology. These systems don't just mix; they orchestrate precise material integration through counter-rotational blades that create unprecedented shear forces and homogeneous blending. The evidence overwhelmingly confirms that contractors clinging to outdated mixing methods are compromising quality, wasting materials, and ultimately delivering inferior results to clients who deserve better.

The Unmatched Mixing Superiority of Planetary Systems

Planetary mixers achieve a level of material consistency that conventional systems simply cannot replicate. Their unique rotating and revolving blade configuration creates three-dimensional mixing action that eliminates dead zones and ensures every particle receives equal attention. This mechanical advantage becomes particularly crucial with modern concrete mixes containing sophisticated admixtures and supplementary cementitious materials that demand perfect dispersion to function as designed.

The homogeneity achieved through planetary mixing directly translates to enhanced concrete performance characteristics. Compressive strength tests consistently show 10-15% improvement over conventionally mixed concrete from the same, while permeability measurements demonstrate significantly reduced void structures. These aren't marginal improvements—they represent the difference between concrete that merely meets specifications and concrete that exceeds them in every meaningful metric.

Operational Efficiency and Material Economy

The argument for planetary mixers extends beyond quality into straightforward economic rationality. These systems on small concrete pump for sale typically achieve complete mixing in 30-50% less time than conventional mixers, directly translating to higher throughput and reduced fuel consumption. More significantly, they require 15-20% less water to achieve equivalent slump values due to superior particle coating and lubrication—a saving that simultaneously improves durability and reduces costs.

Material waste becomes virtually nonexistent with planetary mixing precision. The consistent output quality eliminates the all-too-common practice of over-designing mixes to compensate for mixing inconsistencies. This precision allows contractors to reduce cement content while maintaining performance specifications, creating substantial savings on every cubic meter produced while simultaneously reducing the environmental impact of their operations.

The Compatibility Advantage with Modern Materials

Contemporary concrete formulations have evolved beyond the capabilities of traditional mixing technology. The complex chemical interactions in modern mixes containing silica fume, fly ash, and sophisticated admixtures demand mixing intensity that only planetary systems can provide. Inadequate mixing leaves these materials partially activated, cheating clients of their specified performance and compromising structural integrity.

The evidence clearly demonstrates that contractors using conventional mixers with modern materials are delivering compromised results. Fiber-reinforced concretes particularly suffer from inadequate mixing, with fibers clumping rather than distributing evenly throughout the matrix. This failure represents both technical and ethical shortcomings—professionals have an obligation to use equipment capable of properly handling the materials they specify.

The construction industry's tolerance for mediocre mixing equipment persists only through collective cognitive dissonance. The data overwhelmingly supports planetary mixer adoption as both quality imperative and financial necessity. Contractors continuing to use outdated mixing technology aren't being conservative—they're being negligent. The time for excuses has passed; the concrete industry must embrace planetary mixing technology on the concrete pump for sale acknowledge its complicity in delivering substandard structures. Great buildings deserve great concrete, and great concrete demands planetary mixing.